EU Policy Landscape

Measures announced in December 2020:

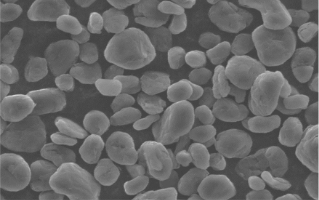

Responsible sourcing. New mandatory procedures to ensure sustainable and

ethical sourcing of raw materials such as graphite.

Carbon (CO2) footprint, performance and durability labelling.

All batteries sold in Europe must declare their carbon footprint.

Traceability.

All raw materials used in batteries to be procured according to OECD recognised guidelines

for sustainable sourcing. Thanks to blockchain technology, each battery will have a digital

passport tracking all upstream components.

Recycling and establishing a circular economy.

A minimum proportion of battery content to be made up of recycled materials. To close the

loop and retain valuable materials used in batteries - such as cobalt, lithium, nickel and

graphite - for as long as possible, the Commission proposes to establish new requirements

and targets on the collection, treatment and recycling of batteries.